|

Chemistry |

Grade |

Density |

Size |

Hardness |

Application Data |

| PIM / MIM Powder |

|

|

|

HR304(L)

Stainless Steel

Powder

Atomized |

Cr:18-20

Ni:8-12

C:0.08(0.03)

Si:1max

Mn:2max

Fe:bal. |

304(L) |

app.4.1-4.5

tap.>4.9

g/cm3 |

150um

75um

45um

15um |

34.5HRC |

MIM part weight:0.03-200g

Apparent relative density>95%

Sinter density>7.6g/cm3

sinter temperature:1360-1380c

Shrinkage rate:1.18 |

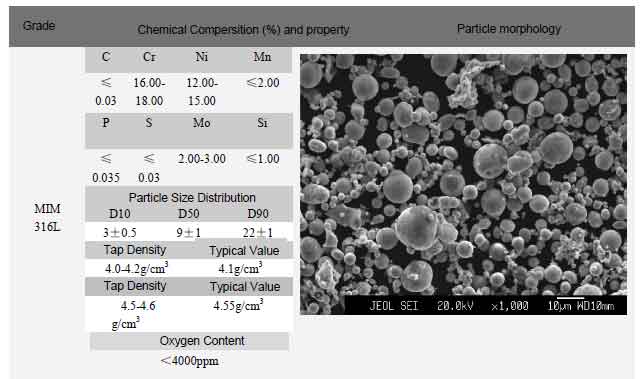

HR316(L)

Stainless steel

powder

Atomized |

Cr:16-18

Ni:10-14

Mo:2-3

C:0.08(0.03)

Si:1max

Mn:2max

Fe:bal. |

316(L) |

app.4.1-4.5

tap.>4.8

g/cm3 |

150um

75um

45um

15um |

36HRC |

MIM part weight:0.03-200g

Apparent relative density>95%

Sinter density>7.8g/cm3

sinter temperature:1360-1380c

Shrinkage rate:1.18 |

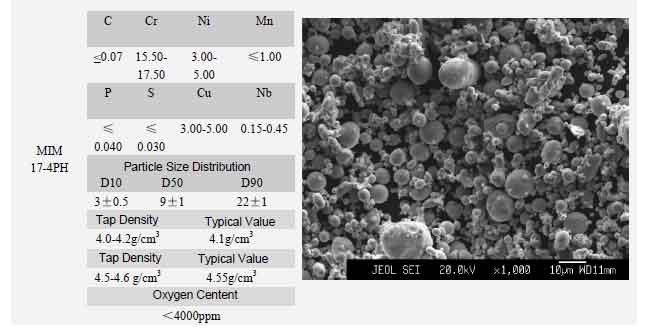

HR174PH

Stainless steel

powder

Atomized |

Cr:15.5-17.5

Ni:3-5

Nb:0.15-0.45

Cu:3-5

C:0.07

Si:1max

Mn:1max

Fe:bal. |

17-4PH |

app.4.1-4.5

tap.>4.8

g/cm3 |

150um

75um

45um

15um |

35HRC |

MIM part weight:0.03-200g

Apparent relative density>95%

Sinter density>7.8g/cm3

sinter temperature:1360-1380c

Shrinkage rate:1.18 |

HR420

Stainless steel

powder

Atomized |

Cr:12-14

C:0.25max

Si:1max

Mn:1max

Fe:bal. |

420 |

app.4.1-4.5

tap.>4.8

g/cm3 |

150um

75um

45um

15um |

HRC50 |

MIM part weight:0.03-200g

Apparent relative density>95%

Sinter density>7.8g/cm3

sinter temperature:1360-1380c

Shrinkage rate:1.18 |

HR430

Stainless steel

powder

Atomized |

Cr:16-18

C:0.12max

Si:1max

Mn:1max

Fe:bal. |

430 |

app.4.1-4.5

top.>4.8

g/cm3 |

150um

75um

45um

15um |

HRC51 |

MIM part weight:0.03-200g

Apparent relative density>95%

Sinter density>7.8g/cm3

sinter temperature:1360-1380c

Shrinkage rate:1.18 |

| HR70Cr |

Cr:65-70

C:0.06(0.03)

Si:1.0max

S:0.03max

P:0.03max |

70Cr |

/ |

-75um

-45um |

/ |

As additive for special part require anti-wear and anti-corrosion, like auto valve shaft guide pipe, seat etc. |

| HR60Mo |

Mo:60-65

C:0.04max

S:0.15max

P:0.06max

Si:1.5max |

60Mo |

/ |

75um

45um

37um

25um |

/ |

As additive for special part require anti-wear and anti-corrosion, like auto valve shaft guide pipe, seat etc. |

| HRCr12Mo |

Cr:10

Mo:1.5

C:0.06

Mn:0.1

S:0.022

P:0.022

Si:1.0

Fe:bal. |

12CrMo |

/ |

75micron

53micron

45micron |

/ |

this alloy powder contain Cr and Mo content, can provide good anti-wear, anti-corrosion performance, it is usually to produce special part which need above performance. |

| HRMnS |

Mn:62-65

S:33-36

O:0.5

Other: 1max |

MnS |

/ |

300mesh

D95:10-12micron |

/ |

As additive, function is lubricaiton. |

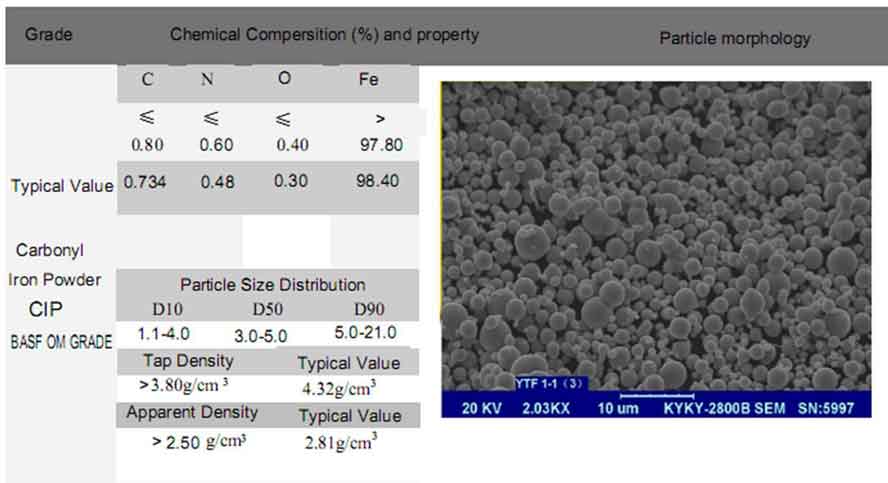

HRFeC1#

Carbonyl Iron powder |

Fe:98%min

C:0.8%max

N:0.6%max

O:0.4%max |

CF1-1 |

App.:2.2min

Tap:4.0min |

D10:0.5-1.0um

D50:2.0ummax

D90:3.0-5.0um |

/ |

/ |

HRFeC1#

Carbonyl Iron powder |

Fe:98%min

C:0.8%max

N:0.6%max

O:0.4%max |

CF1-2 |

App.:2.5min

Tap:3.9min |

D10:0.6-1.5um

D50:2.0-3.0um

D90:4.5-8.0um |

/ |

/ |

HRFeC1#

Carbonyl Iron powder |

Fe:98%min

C:0.8%max

N:0.6%max

O:0.4%max |

CF1-3 |

App.:2.5min

Tap:3.8min |

D10:1.0-3.0um

D50:3.0-5.0um

D90:5.0-12.0um |

/ |

/ |

HRFeC1#

Carbonyl Iron powder |

Fe:98%min

C:0.9%max

N:0.7%max

O:0.4%max |

CF1-4 |

App.:2.2min

Tap:3.5min |

D10:1.5-3.5um

D50:5.0-6.0um

D90:11.5-16.5um |

/ |

/ |

HRFeC2#

Carbonyl Iron powder |

Fe:99.5%min

C:0.05%max

N:0.01%max

O:0.2%max |

CF2-2 |

App.:2.5min

Tap:3.8min |

D10:0.9-3.0um

D50:3.0-5.0um

D90:5.5-12.0um |

/ |

/ |

HRFeC2#

Carbonyl Iron powder |

Fe:99.5%min

C:0.05%max

N:0.01%max

O:0.2%max |

CF2-3 |

App.:2.5min

Tap:3.6min |

D10:1.5-3.0um

D50:5.0-8.0um

D90:10-18um |

/ |

/ |

| Other Carbonyl Iron powder |

|

|

|

|

|

we have more than 20grades, please contact our sales to get more details |

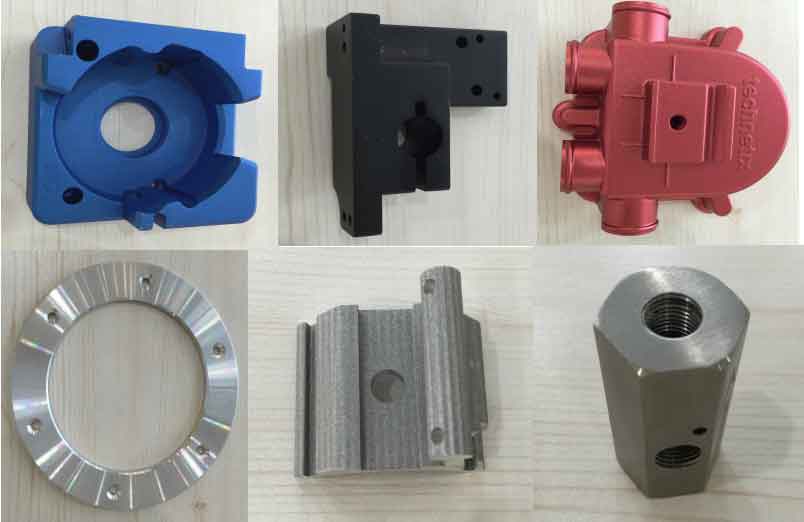

Metal injection molding (MIM) is an effective way to produce complex and precision-shaped parts from a variety of materials. This process produces parts for 50% less than the cost of CNC machining or casting. MIM is able to produce parts with complex shapes, superior strength and excellent surface finish with high volume manufacturing.

Metal injection molding (MIM) is an effective way to produce complex and precision-shaped parts from a variety of materials. This process produces parts for 50% less than the cost of CNC machining or casting. MIM is able to produce parts with complex shapes, superior strength and excellent surface finish with high volume manufacturing.

Our services include prototyping, design, in-house tool production, wire EDM, specialist tool transfer service, high-quality manufacturing and logistics. We specialize in pressed metal parts with tolerances as low as one micron. Press from 5 tons to 160 tons.

Our services include prototyping, design, in-house tool production, wire EDM, specialist tool transfer service, high-quality manufacturing and logistics. We specialize in pressed metal parts with tolerances as low as one micron. Press from 5 tons to 160 tons.