Precision CNC machining services by MiMIndistries are provided for industries such as automotive, construction, medical and other. We are experts in milling, drilling, turning, boring, knurling, reaming, grinding, polishing, deburring , tapping, and external and internal thread cutting. We also offer broaching, slotting, and deep hole drilling. Featuring 2- and 3-axis machinery, our shop is equipped with CNC controlled vertical and horizontal lathes, vertical machining centers, and twin spindle machines.

We work with cast iron, stainless steel, aluminum, steel, brass, copper, bronze, and nickel as well as non-metals such as ABS, acetal, acrylic, fiberglass reinforced plastics, nylon, phenolics, PTFE, and UHMW enabling us to produce a wide variety of products. Our capabilities enable us to fabricate products that measure up to 24” in diameter and up to 30” long. We have a lifting capacity of 2 tons and work to tightest tolerances of ±.0002”.

MiMIndistries has over 30 years of experience in machining services and offers outstanding customer service and turnaround time. More on our precision CNC machining service capabilities can be found in the following table. Contact us directly to speak with one of our skilled representatives.

CNC Machining specification

| Material: | Aluminium6061/6063/7075/5052 etc, Stainless steel303/304/400/316, SteelQ235,20#,45#etc, Brass:C36000(C26800), C37700(HPb59),C38500(HPb58),C2200(CuZn37), C28000(CuZn40) etc, Copper;Beryllium bronze copper. |

| Process: | CNC turning,CNC milling, CNC grinding;CNC lathe machining, CNC boring;CNC drilling, surface treatment |

| Surface treatment: | Hardness anodizing black/clear, steel oxidizing dark-blue, electro-polishing, electroless nickel plating, silver plating, golden plating etc |

| Tolerance: | +/-0.001mm or +/- 0.00004″ |

| Certification: | ISO9001:2008, ROHS |

| Production capacity: | depend on complicacy of different products and the quantity |

| Experience: | 15 years of CNC machining products /2 years of automation machine manufacturing |

| Packaging : | standard export carton with pallet or as per customes’requirement |

| Lead time : | making arrangement upon customers’request |

| Term of Payment: | T/T, L/C, Escrow, paypal, western union |

| Part size: | Diameter from 0.5mm to 1000mm |

| Minimum Order: | Comply with customer’s demand |

| Delivery way: | EXPRESS, BY SEA OR BY AIR on your requirement. |

| Maine equipment: | Machining center, CNC, Lathe, Turning machine, Milling machine, Drilling machine, Internal and external grinding machine, Cylindrical grinding machine, Tapping drilling machine, Wire cutting machine etc. |

| Testing facility: | Coordinate measuring machine, projector, roughness tester, hardness tester, concentricity tester. Height tester, . |

| Item Tag | mini cnc milling machine for sale |

|

MEASURING CAPABILITY |

|||

| Measurement | Range(mm) | Accuracy(um) | Brand |

| Length | 200×150

700×600×500 0-600 |

3+L/50

2.1+3.8L/1000 3+L/300 |

Easson(Taiwan)

Brown & Sharpe(Us) Trimos/Tesa(Swiss) |

| External Diameter | 0-100 | 1 | Mitoyuto(Japan) |

| Internal Diameter | 5-30 | 1 | Tesa (Swiss) |

| Surface Roundness | 80 | 0.01 | Mitoyuto(Japan) |

|

General Tolerance(+/-mm) |

|

| CNC Machining | 0.005 |

| Turning | 0.005 |

| Grinding(Flatness/in2) | 0.003 |

| ID/OD Grinding | 0.002 |

| Wire-Cutting | 0.002 |

|

MAXHINING EQUIPMENT |

|

| CNC Machining | Sheet Metal |

| High Speed

Vertical Machining Horizontal Machining CNC Turning |

CNC Blanking

Hydraulic Shearing Hydraulic Press Welding |

| Grinding | W/C Machining |

| Jig Grinding

Center-less Grinding Surface Grinding ID/OD Cylindrical Grinding Ceramic Grinding |

Wire Cut

Drilling |

| General Machining | Others |

| NC Turning Lathe Milling |

Lapping Heat Treatment Surface Treatment |

Product materials of cast iron, cast steel, super duplex, SST, copper based & aluminum based alloys.

- CNC milling (Aluminum, brass, steel, zinc alloy, many others )

- Sheet metal (Steel, Aluminum, many others)

- Die Casting (ADC12,etc);

- Finish :remove bur, sandblast, anodized, painting, printing, plating, high polish, mirror polish, blackening, powder coating, etc.

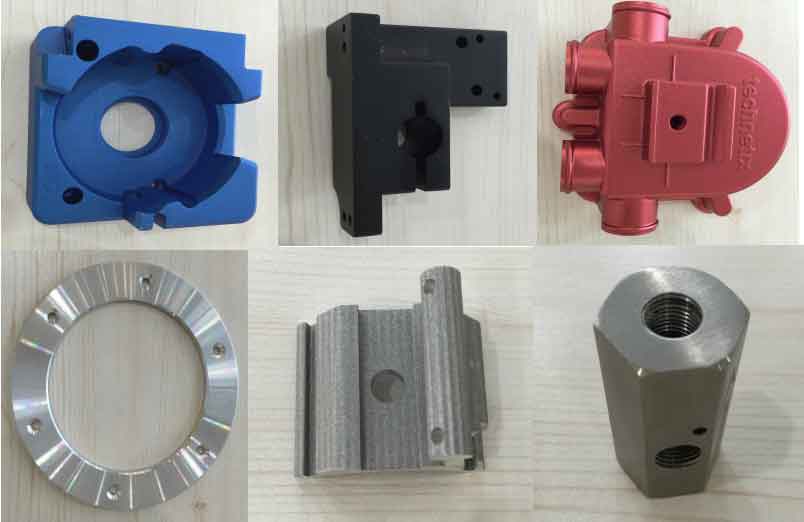

Here below please find some pictures we have made recently:

To successfully make a part on a CNC Machine, programs instruct the machine how it should move. The programmed instructions given to the CNC machine are encoded using CAM (computer aided manufacturing) software in conjunction with the CAD (computer aided design) model provided by the customer.

The CAD model is loaded into the CAM software and tool paths are created based on the required geometry of the manufactured part. Once the tool paths are determined, the CAM software creates machine code that tells the machine how fast to move, how fast to turn the stock and/or tool, and where to move in a 5-axis X, Y, Z, A and B coordinate system.

Contact us to learn more about the MiMsactories advantage for the CNC Machining Services.

Small - medium - high order quantity

FOR FAST QUOTE EMAIL US: 2D/3D DRAWINGS