In precision casting, parts can be cast from steel and stainless steel. Often referred to as investment casting or lost wax casting, this process uses specialized wax materials to create molds. The wax is then encased in a ceramic shell that creates an exact—and far more durable—replica of the wax mold. The wax is melted and removed, and the ceramic mold is used to produce the cast parts.

Investment casting allows for more intricate and complex forms than other casting methods, and can be used to produce parts that would be difficult or impossible to create through other processes (machining, fabrication, etc.). It tends to yield parts and components with very good surface finishes, which can reduce or eliminate the need for additional finishing work.

Precision Casting Advantages

Precision casting offers many distinct advantages over other casting methods, some of which include:

- High dimensional accuracy

- Excellent surface finish

- Able to cast extremely intricate parts

- No flash or parting lines

- Almost any metal can be cast

Precision casting is generally used to produce smaller parts, but large and/or heavy products can be accurately cast using this process, as well. Contact us to learn more or request a quote today.

Product materials of cast iron, cast steel, super duplex, SST, copper based & aluminum based alloys.

- CNC milling (Aluminum, brass, steel, zinc alloy, many others )

- Sheet metal (Steel, Aluminum, many others)

- Die Casting (ADC12,etc);

- Finish :remove bur, sandblast, anodized, painting, printing, plating, high polish, mirror polish, blackening, powder coating, etc.

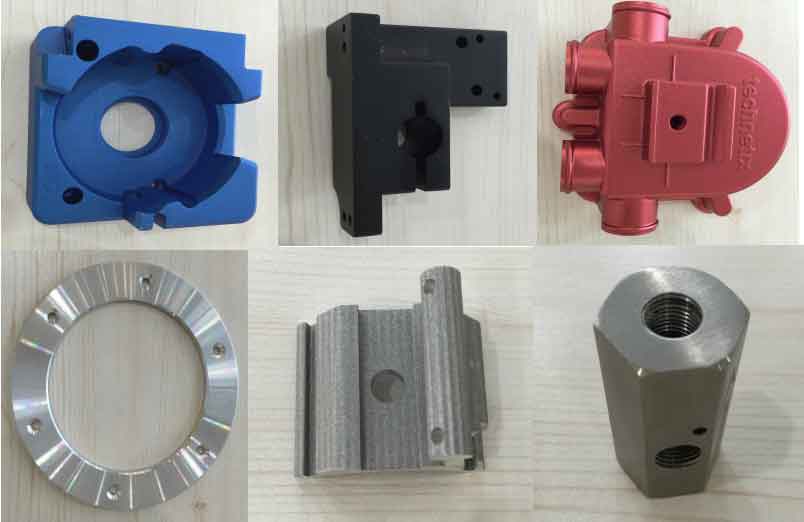

Here below please find some pictures we have made recently:

Small - medium - high order quantity

FOR FAST QUOTE EMAIL US: 2D/3D DRAWINGS