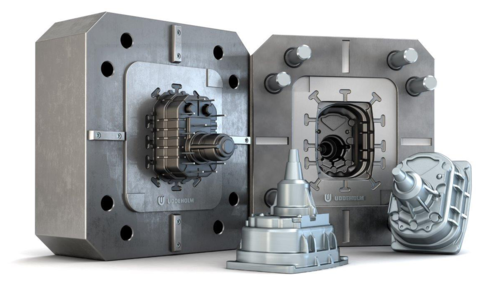

Die casting can be used to produce parts from zinc and aluminum, and is ideal for smaller pieces and more intricate part designs. Molds for die casting are created from hardened tool steel which is machined into the desired shape. Like those used in sand casting, die casting molds are built in two halves, which are separated after casting to remove the resulting part(s).

Molten metal is forced into the mold cavities under high pressure (up to 25,000 psi or greater), and this pressure is maintained until the casting cools and solidifies.