Description

– Cobalt alloy Excellent wear and corrosion resistance even at high temperature up to 800℃

SYTOP cobalt base alloys is a range of cobalt-chromium-tungsten alloys with wear resistance, corrosion and high thermal resistance. It is widely used in oil & gas, machinery, wood cutting, automotive, paper and food processing industry etc.

Cobalt Alloy Chemical compositions and properties (%)

| Name

Cobalt-chromium Alloy ‘CCA’ |

C | Mn | Si | Cr | Ni | Mo | W | Co | Fe | P | S | Density

(g/cm³) |

Hardness

(HRC) |

| CCA-3 | 2.0-2.7 | 1.0 | 1.0 | 29-33 | 3.0 | 11-14 | Bal. | 3.0 | ≤0.03 | ≤0.03 | 8.55 | 51-55 | |

| CCA-6 | 0.9-1.4 | 1.0 | 1.5 | 27-31 | 3.0 | 1.5 | 3.5-5.5 | Bal. | 3.0 | ≤0.03 | ≤0.03 | 8.35 | 38-44 |

| CCA-12 | 1.1-1.7 | 1.0 | 1.0 | 28-32 | 3.0 | 7.0-9.5 | Bal. | 3.0 | ≤0.03 | ≤0.03 | 8.40 | 44-49 | |

| CCA-20 | 2.2-3.0 | 2.0 | 30-34 | 3.0 | 1.0 | 14-18 | Bal. | 3.0 | ≤0.05 | ≤0.05 | 8.65 | 53-59 | |

| MF-M 25 | 2.2-2.8 | 1-3 | 27-32 | 7 | Ta/Nb | 14-19 | Bal. | 2-5 | 8.84 | 57-60 | |||

| MF-M 35 | 3.3-3.8 | 1-3 | 27-32 | 7 | Ta/Nb | 14-19 | Bal. | 2-5 | 8.80 | 60-63 | |||

| MF400 | 0.04 | 2.5-2.7 | 8-10 | 27-29 | Bal. | 55 | |||||||

| MF800 | 0.04 | 3.2-3.6 | 16-18 | 27-29 | Bal. | 58 |

Specifications that we can made :

Specifications that we can made :

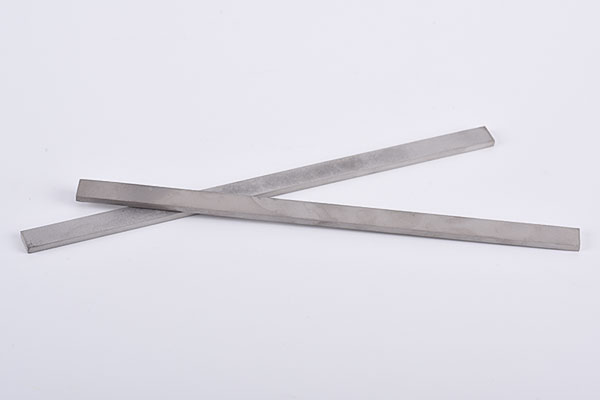

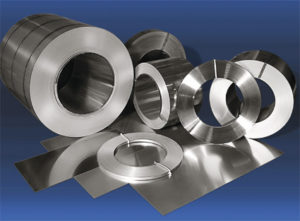

Different size bars, rods, ingots, plate

Drawing made seal , valve seat and ball , bush and sleeve etc.

Some size tube

Most of our products are made upon request so contact us right now for personal and professoinal service.